| |

2D/3D Laser Marking System

LMS-6000

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

LMS-6000 System Overview |

|

|

| |

Based on a Pulsed Solid State Laser System, which has a laser that features a 532nm wavelength and 10ns pulse width. This system can produce a refined 2D/3D graphics under the surfaces of clear substance like crystals glass. This system is controlled by personal computer and professional motion adapter. The following are several features and advantage for LMS over other systems.

- State-of-the-Art component

- All-in-One Integrated System

- High Performance

- S implified Operation

- Easy Mobility

- Easy Maintenance

- Applied for most general transparent materials and artifacts

|

|

| |

|

|

|

| |

LMS-6000 C5 Version Software |

|

|

| |

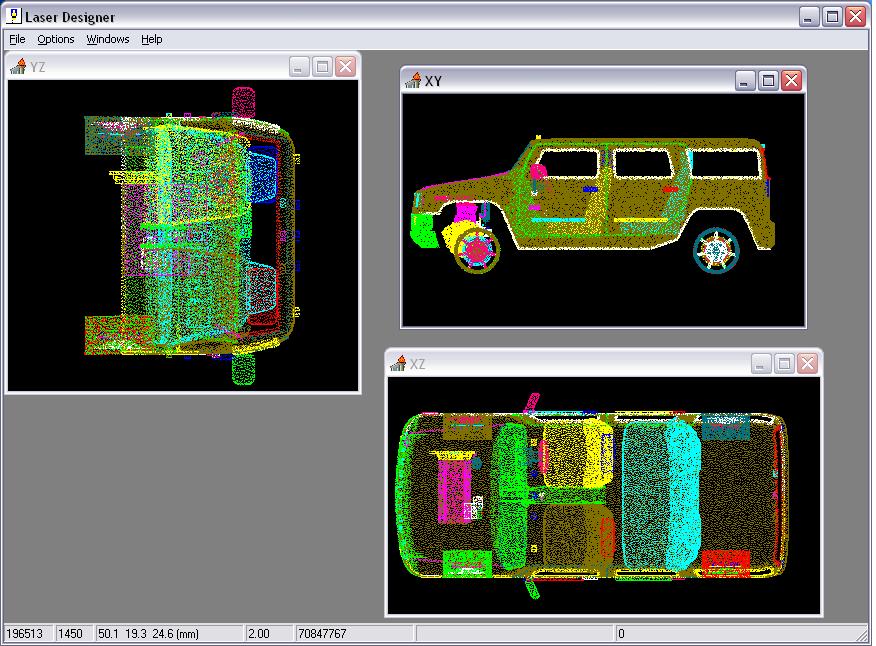

Main Screen

Description

This software was develop to process images into a readable data format for the D5 beam output software C5 allows the user to modify the image to create a efficient file for D5 beam export software to process. The following is part of a full list of functions that C5 is able to perform:

- Process DXF, BMP, 3DS, and desBMP files

- Change number for layers for 2D photos

- Change the pattern at which the lasers are laid out for 2D/3D images

- Change the distance between vertical and horizontal points

- Change the density of the point

|

|

| |

|

|

|

| |

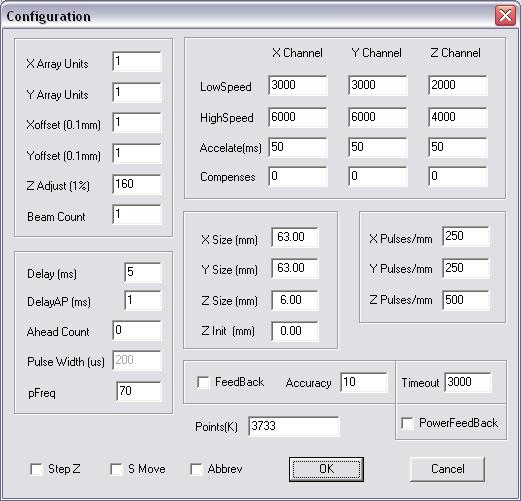

LMS-6000 D5 Version Software |

|

|

| |

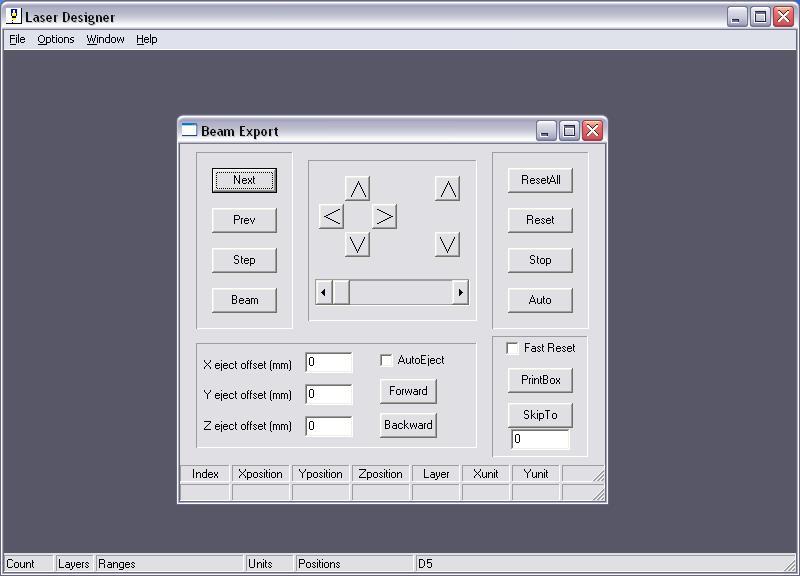

Main Screen

Description

This software was develop to execute data files processed in C5 software. D5 allows the users to control the LMS-6000 Laser Marking System to export the beams from the system to burn the points into the crystal. D5 controls every little movement that is executed my LMS-6000. Most importantly, D5 is used to set the parameters for the image and the object to align correctly.

|

|

| |

|

|

|

| |

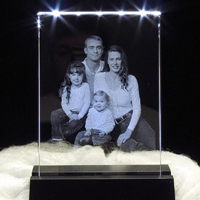

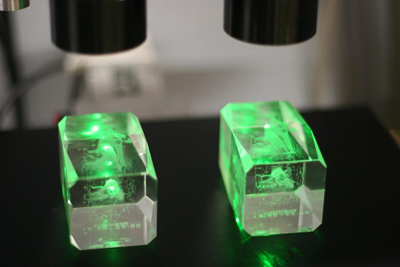

Samples of LMS-6000 |

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

| |

LMS-6000 Technical Data & Specifications: |

|

|

| |

Laser medium |

(Nd, Ce):YAG crystal, lamp pumped, 532 nm |

|

| |

Nominal Energy |

3 mJ (TEM00) |

|

| |

Pulse width |

<= 12 ns |

|

| |

Stability |

+/- 2% (pulse to pulse) |

|

| |

Pulse frequency |

1 – 200 Hz (programmable) |

|

| |

Electrical connection |

220V +/- 10% |

|

| |

Power consumption max. [kW] |

3000W |

|

| |

Connecting cables |

2 m for electric cables and 3 m I/O cable |

|

| |

|

|

|

| |

Typical features: |

|

|

| |

Minimal diameter of a point |

40 um |

|

| |

Max diameter of a point |

400 um |

|

| |

Max marking range (2 / 3 / 4 lens) |

300*200*100 mm |

|

| |

Marking range (2 / 3 / 4 lens) |

300*120*100 mm |

|

| |

Marking lens |

3 |

|

| |

Max marking rate |

110 points per second |

|

| |

Performance (points per minute) |

3000-6000 points per minute |

|

| |

Positioning accuracy |

5 um |

|

| |

|

|

|

| |

Physical Dimension: |

|

|

| |

Dimensions (L x W x H; mm) |

880 x 680 x 1200 |

|

| |

Weight |

Approx. 220 kg |

|

| |

Structure |

Light Weight Metal Structure |

|

| |

Color |

Silver with black panels |

|

| |

Panels |

Plexi-Glass |

|

| |

Panel Color |

Black |

|

| |

Documentation |

1 x |

|

| |

|

|

|

| |

Operation Environment Demands: |

|

|

| |

Room Temperature: |

20-25 C |

|

| |

Room Humidity: |

< 60% |

|

| |

|

|

|

| |

Heat Dissipater: |

|

|

| |

Dissipater Type |

Water Heat Exchanger |

|

| |

Flow |

30 Liter per minute |

|

| |

Connection |

¾-inch screwing |

|

| |

Output Cooling |

1500 W |

|

| |

Sound level |

30 dB(A) |

|

| |

|

|

|

| |

Graphics Processing PC |

Minimum Requirements... |

|

| |

PC Type |

Desktop or Labtop |

|

| |

CPU Speed |

2.7 GHZ or greater |

|

| |

RAM Memory |

512 MB or greater |

|

| |

HD |

40 GB or greater |

|

| |

OS |

Windows 2000 or XP |

|

| |

VGA Board & Monitor |

Minimum Screen Resolution 1280 x 1024 |

|

| |

Media Support |

CD-RW, CD+RW |

|

| |

Connections Requirements |

1 Parallel, 1 Serial, and USB |

|

| |

Other Hardware |

Mouse and Keyboard |

|

| |

|

|

|

| |

LMS System Control PC |

Minimum Requirements... |

|

| |

PC Type |

Desktop or Labtop |

|

| |

CPU Speed |

1.7 GHZ or greater |

|

| |

RAM Memory |

256 MB or greater |

|

| |

HD |

40 GB or greater |

|

| |

OS |

Windows 2000 or XP |

|

| |

VGA Board & Monitor |

Minimum Screen Resolution 1280 x 1024 |

|

| |

Media Support |

CD-ROM |

|

| |

Connections Requirements |

1 Parallel, 1 Serial, and USB |

|

| |

Other Hardware |

Mouse and Keyboard |

|

| |

|

|

|

| |

Sub-Surface Laser Engraving Process |

|

|

| |

SSLE is an exciting new process that is capturing the imagination of thousands. The technology is quite special, but it can be explained easily. In a nutshell, sub-surfacing laser engraving is the process that consists in taking a 2D and/ or 3D picture of someone and then engraving that image into a crystal cube.

This process uses a scientific laser that's driven by a SSLE, a sophisticated computer graphical program, that will create your actual 2D or 3D image within a flawless piece of optically perfect and clear solid crystal block. Concentrated laser beams are programmed by SSLE to penetrate and create a single micro pixel dot within the crystal. These powerful laser beams are highly focused on a single predetermined microscopic point. This process uses a scientific laser that's driven by a SSLE, a sophisticated computer graphical program, that will create your actual 2D or 3D image within a flawless piece of optically perfect and clear solid crystal block. Concentrated laser beams are programmed by SSLE to penetrate and create a single micro pixel dot within the crystal. These powerful laser beams are highly focused on a single predetermined microscopic point.

The Laser system then refocuses to burn yet another seemingly insignificant particle of the crystal at another exact point within your project. Following a precise sequence, these laser inscribed points combine to form the completed image in exquisite detail. Depending on the size and detail of your project this process could possibly be repeated millions of times in order to create your amazing 2D or 3D image. From a simple and delicate design to an exceedingly complex graphical assignment, the 2D/3D laser inscribing process can create the perfect object of astonishment.

Since our laser is non-invasive, the inscribing process leaves no marks or inaccuracies on the surface of the highly polished K9 crystal. When viewed from any angle the intricate design appears like a 3D sculpture. Beams of light are refracted in tens of thousands of directions creating a dramatic presentation from all viewing angles. Your collectible piece of K9 Crystal Art work is timeless and should be appreciated by even the most discerning individuals.

The design process for a laser crystal piece can take up to several weeks, depending on your needs. From designing visual concepts of the image, research, gathering source photos and models, to reviewing possible changes, no detail will be overlooked during the creation of your custom art work. Once we have a final model, US Design Int'l Inc. will continue onto the computer assisted drafting process to generate your true 3D images or the original (final model). Each "dot" or point at which the laser will be fired must be precisely placed. Only after all refinements are made will your final design be run to create your laser ready version.

US Design Int'l Inc. have several different qualities of optically perfect crystal. The only difference between each product is the percentages of the lead content within the crystal. Our need for high quality crystal is simply to allow the laser beam to focus precisely inside the solid block of crystal, undisturbed by flaws. Your design could contain anywhere from tens of thousands to millions of laser pixel points that are infused directly into a solid block of crystal. Larger projects could take upwards of 2 hours for each piece for the laser machine to place all its millions of predetermined pixel points, making your design exclusively yours. After your piece is finished, our company will clean and inspect the results to ensure the quality that you and our company expect is met.

This amazing process results in the thrill of getting a stunningly flawless K9 Crystal with an image that affirms your appreciation. Holding your Custom Laser Inscribed Crystal while turning it in their hands and changing the viewing angle helps everyone to appreciate the fine craftsmanship and efforts that goes into designing and producing each K9 Crystal Art piece. Not to mention the inevitable “That's nice!!! How did they do that?” reaction everyone experiences when they first view these unique piece of work.

|

|

| |

|

|

|